Informative

Unlocking Efficiency and Innovation: The Benefits of Outsourcing Custom Parts Manufacturing to CNC Machining Shops

Unlocking Efficiency and Innovation: The Benefits of Outsourcing Custom Parts Manufacturing to CNC Machining Shops

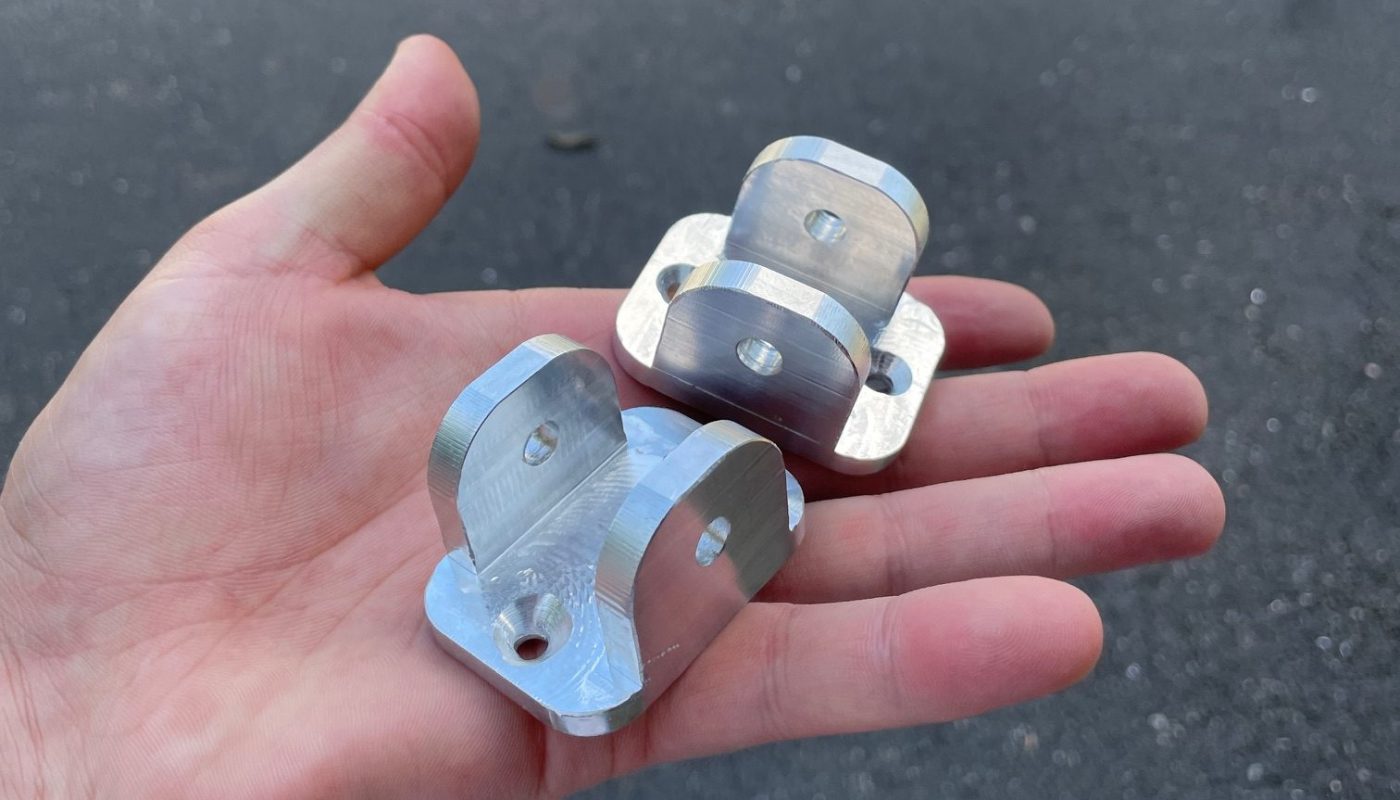

In today’s fast-paced business landscape, companies across various industries are constantly seeking ways to streamline their operations while maintaining the highest standards of quality and precision. When it comes to custom parts manufacturing, outsourcing to specialized CNC machining shops has emerged as a strategic solution, offering a multitude of benefits that can propel businesses forward.

Cost Savings Without Compromise

One of the most compelling reasons to outsource custom parts manufacturing is the significant cost savings it can bring. Specialized CNC machining shops often operate with economies of scale, allowing them to optimize production processes and reduce overhead costs. This translates into more competitive pricing for custom parts without sacrificing quality or accuracy. By outsourcing, businesses can avoid the hefty investment required for in-house machining equipment, maintenance, and skilled labor, freeing up valuable resources to invest in core business activities.

Access to Cutting-Edge Technology

In the ever-evolving landscape of manufacturing technology, staying ahead of the curve is crucial for maintaining a competitive edge. CNC machining shops are equipped with state-of-the-art machinery and software, offering access to advanced manufacturing technologies that may be out of reach for many businesses. From multi-axis machining centers to computer-aided design (CAD) and computer-aided manufacturing (CAM) software, these facilities are equipped to handle complex projects with precision and efficiency. By outsourcing custom parts manufacturing, businesses can leverage the expertise and capabilities of CNC machining shops to bring their designs to life with unparalleled accuracy and consistency.

Faster Turnaround Times

In today’s fast-paced market, speed is of the essence. Outsourcing custom parts manufacturing to CNC machining shops allows businesses to benefit from faster turnaround times compared to traditional in-house machining. With streamlined production processes, optimized workflows, and dedicated teams focused solely on manufacturing, CNC machining shops can deliver custom parts with shorter lead times without compromising on quality. Whether it’s prototyping, small-batch production, or high-volume manufacturing, outsourcing ensures that deadlines are met and projects are delivered on time, enabling businesses to respond swiftly to market demands and opportunities.

Maximizing Efficiency and Focus

Outsourcing custom parts manufacturing not only drives cost savings, access to advanced technology, and faster turnaround times but also allows businesses to maximize efficiency and focus on their core competencies. By entrusting manufacturing tasks to specialized CNC machining shops, businesses can redirect their time, resources, and expertise towards innovation, product development, and strategic initiatives. This strategic shift not only enhances productivity but also enables businesses to stay agile and adaptable in today’s dynamic marketplace.

In conclusion, outsourcing custom parts manufacturing to specialized CNC machining shops offers a myriad of benefits that can propel businesses towards success. From cost savings and access to advanced technology to faster turnaround times and increased efficiency, the advantages are clear. By partnering with the right CNC machining shop, businesses can unlock new levels of efficiency, innovation, and competitiveness, positioning themselves for sustained growth and prosperity in the years to come.